How to Choose a Solenoid Valve? Quality and Performance Are the Key Criteria

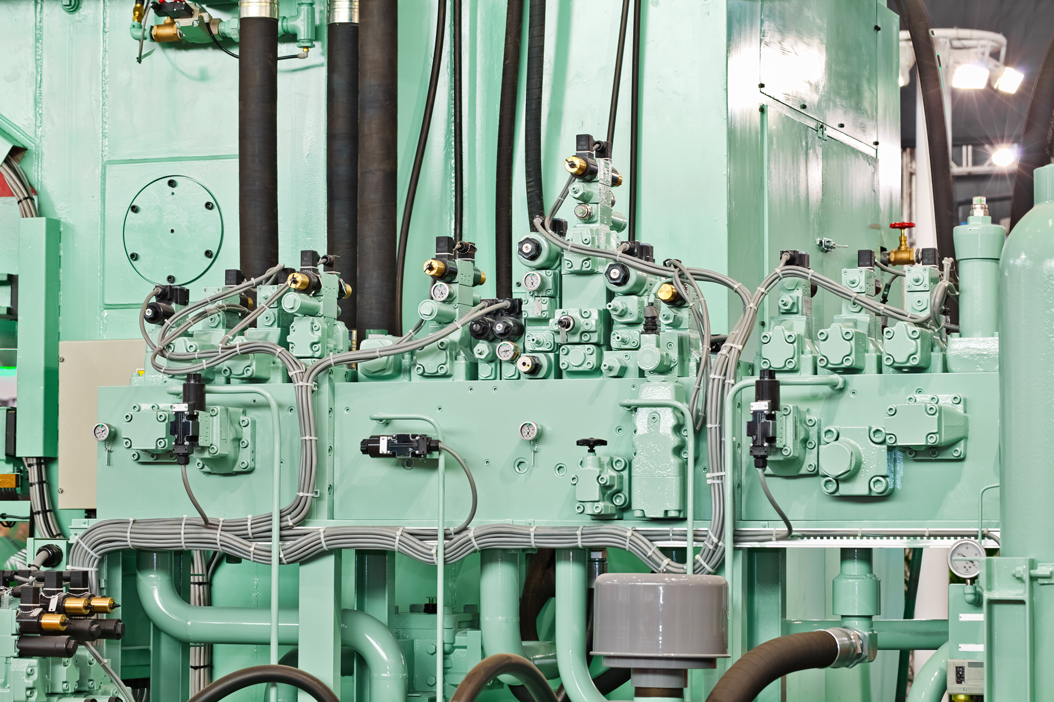

Solenoid valves are indispensable control components in industrial applications. They enable fast and accurate control of the flow of liquids or gases for flow control, pressure control and automated operation. However, it is not easy to choose among solenoid valves to determine the optimal product for installation. Therefore, when selecting solenoid valves, we need to evaluate the alternatives against a set of criteria to make sure the solenoid valve can deliver desired quality and performance.

Determine your application needs. Before purchasing solenoid valves, it is essential to confirm your application requirements. These requirements include controlling the flow rate and pressure of liquids or gases and special features such as waterproof or corrosion protection. Having this checklist will help us screen the solenoid valves that meet our application requirements.

Confirm flow and pressure range. Ensure that the selected solenoid valve has the required flow capacity and pressure range. Check the rated flow rate and maximum working pressure of the valve against the application requirements. This check will ensure that the valve can effectively handle the flow of liquids or gases in the system.

- Confirm Media Compatibility - Determine if the selected solenoid valve works for the desired medium, such as water, air, oil, etc. Different media have different temperature ranges, chemical properties and viscosity. For example, oil or highly viscous liquids may be more viscous than water, and therefore the valve viscous liquids as medium needs to have sufficient capacity to ensure smooth and proper flow.

- Confirm the Control Mode - Solenoid valves have different operating principles (such as direct-acting and pilot-operating) and trigger mechanisms (such as power-on opening and power-off closing valves). When selecting a valve, we need to determine whether the control mode of the selected valve meets the application system’s requirement to ensure the system’s normal operation.

- Whether There Are Special Functional Requirements - Some applications may require solenoid valves with special functions or characteristics. For example, some applications may require special functions or characteristics, such as explosion-proof function, high corrosion resistance, and low power consumption. We must select the most suitable product for the specific application needs. If there are special requirements in your application environment, it is recommended to communicate with the supplier and confirm whether the chosen solenoid valve has the corresponding special function.

When purchasing solenoid valves, on top of focusing on the product itself, it is also important to choose a supplier that can provide consistent quality and highly reliable products. As a supplier, Chia Wang has a competitive advantage in price and pays attention to on-time delivery to meet customer needs. In addition, Chia Wang provides professional technical support and perfect after-sales service to ensure that customers have no worries after purchase. By mastering the key criteria of selecting solenoid valves, you will be able to select products with both quality and performance to optimize your application needs.